By Williams | 26 August 2025 | 0 Comments

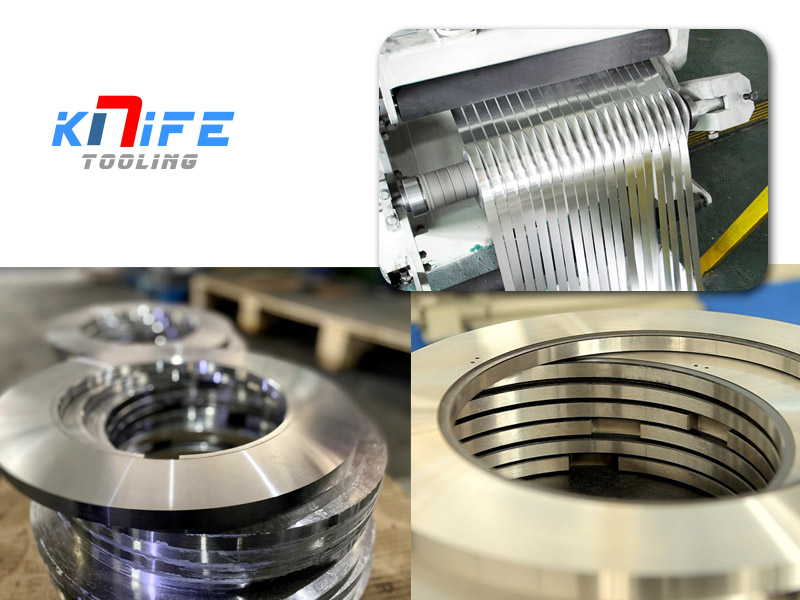

Highlights of Knifetooling’s Ultra-Precision Slitting Knives

As technology advances, slitting technology continues to gain greater market traction—especially the multifunctional integration of ultra-precision slitting solutions. This innovation delivers far-reaching impacts across the manufacturing sector, driving positive, critical improvements in production efficiency, cost control, product quality, and overall industrial development.

In the special field of ultra-precision silicon steel coil slitting, Knifetooling’s tools stand out with three core technical advantages:

1. G17 Cemented Carbide Innovation

To address key pain points in silicon steel slitting—such as rapid blade wear and chipping—Knifetooling has co-developed its proprietary G17 cemented carbide. This material features a fine-grain structure (≤1μm) and a hardness rating of up to 62 HRC (SGS-certified). Compared to standard tungsten carbide (TC) blades, G17 offers a 250% longer service life**: it achieves over 250 km of slitting per regrind cycle, while ordinary TC blades typically only reach around 100 km. Additionally, G17 resists chipping even during high-speed processing.

2. Micron-Level Precision Machining

Equipped with 15 advanced grinding machines, Knifetooling implements a multi-stage machining process:

- Coarse grinding (3μm) efficiently removes excess material;

- Fine grinding (1μm) enhances flatness and parallelism;

- Polishing refines surface finish.

For blades with an outer diameter of ≤250 mm, this process ensures a thickness tolerance of ±0.001 mm and flatness of ≤0.001 mm—critical for maintaining stable shear gaps during operation.

3. High-Grade Surface Treatment

Knifetooling offers four surface treatment options to meet diverse application needs:

- Grinding (Ra 0.324μm) for general precision requirements;

- Lapping (Ra 0.192μm) for improved smoothness;

- Polishing (Ra 0.091μm) for enhanced sharpness;

- Mirror polishing (Ra 0.016μm) for ultra-high-precision scenarios.

Notably, mirror polishing reduces friction by 30%, minimizing microcracks on the blade edge and extending overall service life.

These technical strengths make Knifetooling the top choice for precision slitting applications. We also welcome consultations and partnerships with sheet metal and generator manufacturers worldwide to share our latest technological advancements.

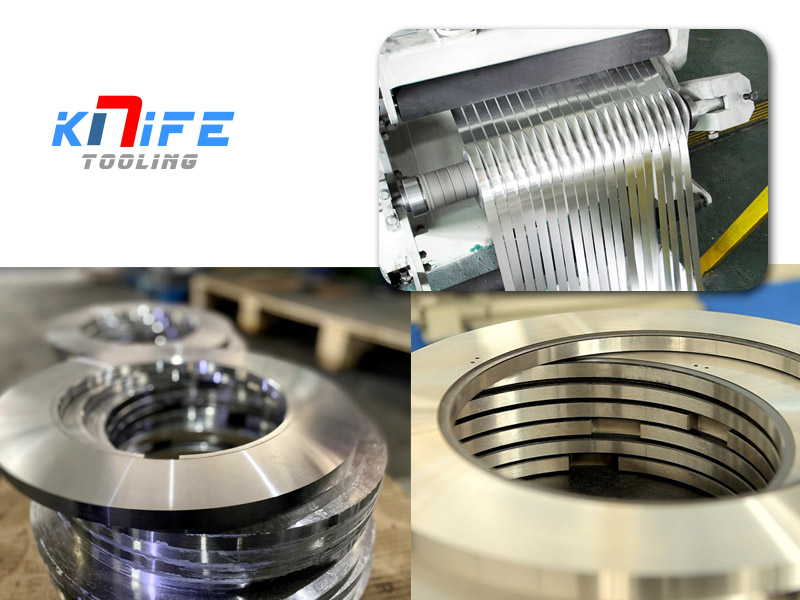

In the special field of ultra-precision silicon steel coil slitting, Knifetooling’s tools stand out with three core technical advantages:

1. G17 Cemented Carbide Innovation

To address key pain points in silicon steel slitting—such as rapid blade wear and chipping—Knifetooling has co-developed its proprietary G17 cemented carbide. This material features a fine-grain structure (≤1μm) and a hardness rating of up to 62 HRC (SGS-certified). Compared to standard tungsten carbide (TC) blades, G17 offers a 250% longer service life**: it achieves over 250 km of slitting per regrind cycle, while ordinary TC blades typically only reach around 100 km. Additionally, G17 resists chipping even during high-speed processing.

2. Micron-Level Precision Machining

Equipped with 15 advanced grinding machines, Knifetooling implements a multi-stage machining process:

- Coarse grinding (3μm) efficiently removes excess material;

- Fine grinding (1μm) enhances flatness and parallelism;

- Polishing refines surface finish.

For blades with an outer diameter of ≤250 mm, this process ensures a thickness tolerance of ±0.001 mm and flatness of ≤0.001 mm—critical for maintaining stable shear gaps during operation.

3. High-Grade Surface Treatment

Knifetooling offers four surface treatment options to meet diverse application needs:

- Grinding (Ra 0.324μm) for general precision requirements;

- Lapping (Ra 0.192μm) for improved smoothness;

- Polishing (Ra 0.091μm) for enhanced sharpness;

- Mirror polishing (Ra 0.016μm) for ultra-high-precision scenarios.

Notably, mirror polishing reduces friction by 30%, minimizing microcracks on the blade edge and extending overall service life.

These technical strengths make Knifetooling the top choice for precision slitting applications. We also welcome consultations and partnerships with sheet metal and generator manufacturers worldwide to share our latest technological advancements.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- Steel Coil Slitting Tool Selection: Knifetooling Eases Your Headache

- Why SGS Matters for Your Slitting Blades: Precision Backed by Global Certification

- Knifetooling: Professional After-Sales Technical Coaching Helps Customers Overcome Tool Resharpening

- Highlights of Knifetooling’s Ultra-Precision Slitting Knives

- How to pick the best slitting knives for best productivity