By Williams | 26 September 2025 | 0 Comments

Why SGS Matters for Your Slitting Blades: Precision Backed by Global Certification

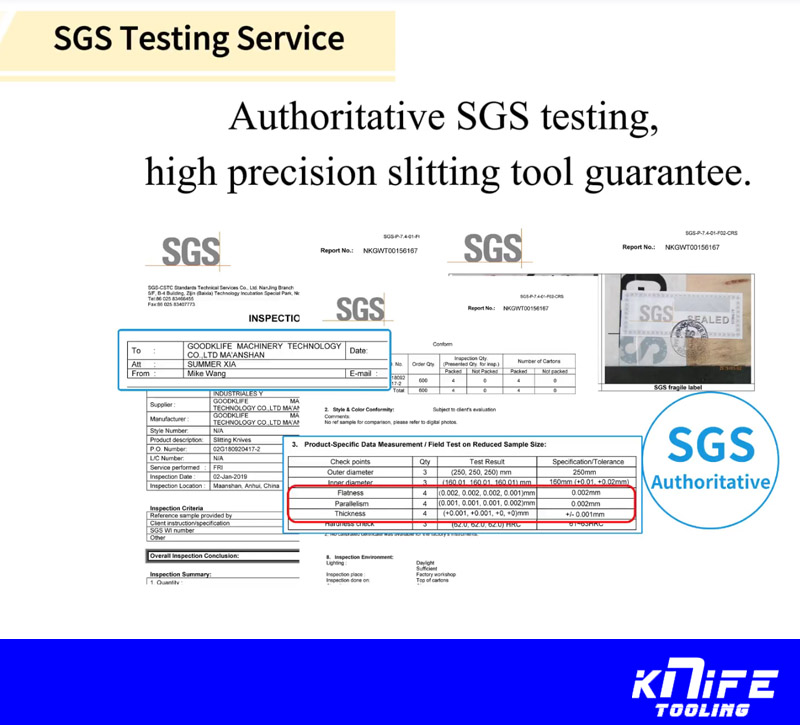

For high-precision slitting tools, precision isn't just a feature; it's essential for improving production efficiency, reducing material waste, and ensuring high-quality end products. That's why we not only produce blades that meet top-tier precision standards, but we also back this up with SGS testing and a comprehensive certification report with every delivery.

Why is SGS certification so important? As a globally recognized leader in inspection, verification, testing, and certification, SGS goes beyond simply checking a box. Their rigorous process provides customers, even those overseas, with a benchmark to measure against:

1. Verifies blade dimensional accuracy (ensuring they meet your machinery and slitting requirements).

2. Tests material durability and wear resistance (keeping your blades sharp longer and minimizing downtime for blade replacements).

3. Confirms compliance with international quality and safety standards (giving you confidence in every cut, regardless of where your business operates).

This isn't just a piece of paper. It means:

A. No more guesswork about our blade performance—SGS's data-backed reports prove our blades' superior performance.

B. Reduces the risk of production errors, rework, or material waste due to tooling inaccuracies.

C. Gain peace of mind knowing your investment in blades meets the exacting standards trusted by industries worldwide.

Whether you're slitting film, foil, paper, or textiles, precision is undeniable. Our SGS-certified, high-precision slitting blades are more than just a tool; they're a guarantee of consistency, reliability, and performance.

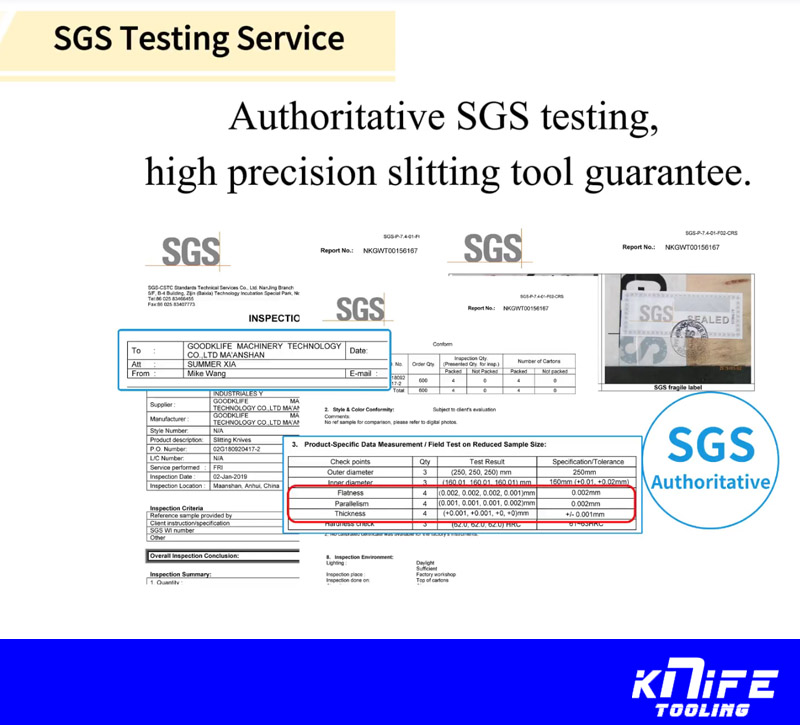

Why is SGS certification so important? As a globally recognized leader in inspection, verification, testing, and certification, SGS goes beyond simply checking a box. Their rigorous process provides customers, even those overseas, with a benchmark to measure against:

1. Verifies blade dimensional accuracy (ensuring they meet your machinery and slitting requirements).

2. Tests material durability and wear resistance (keeping your blades sharp longer and minimizing downtime for blade replacements).

3. Confirms compliance with international quality and safety standards (giving you confidence in every cut, regardless of where your business operates).

This isn't just a piece of paper. It means:

A. No more guesswork about our blade performance—SGS's data-backed reports prove our blades' superior performance.

B. Reduces the risk of production errors, rework, or material waste due to tooling inaccuracies.

C. Gain peace of mind knowing your investment in blades meets the exacting standards trusted by industries worldwide.

Whether you're slitting film, foil, paper, or textiles, precision is undeniable. Our SGS-certified, high-precision slitting blades are more than just a tool; they're a guarantee of consistency, reliability, and performance.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- Steel Coil Slitting Tool Selection: Knifetooling Eases Your Headache

- Why SGS Matters for Your Slitting Blades: Precision Backed by Global Certification

- Knifetooling: Professional After-Sales Technical Coaching Helps Customers Overcome Tool Resharpening

- Highlights of Knifetooling’s Ultra-Precision Slitting Knives

- How to pick the best slitting knives for best productivity