By Williams | 26 August 2025 | 0 Comments

Knifetooling: Professional After-Sales Technical Coaching Helps Customers Overcome Tool Resharpening

During the application of cutting tools, enterprises often encounter various technical troubles that adversely affect production efficiency and cost management. To effectively safeguard customer rights and interests, Knifetooling has established a professional technical team, which always adheres to the service principle of "customers are first". It not only provides all-round technical services and coaching for enterprises purchasing slitting tools, proactively popularizes cutting-edge industry technologies, but also customizes technical upgrade solutions for practical problems encountered by customers, helping them efficiently resolve production difficulties.

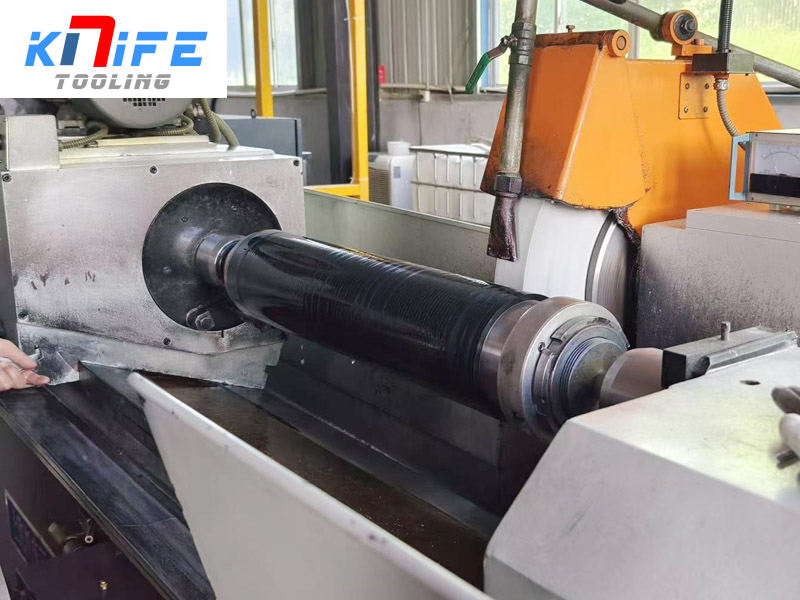

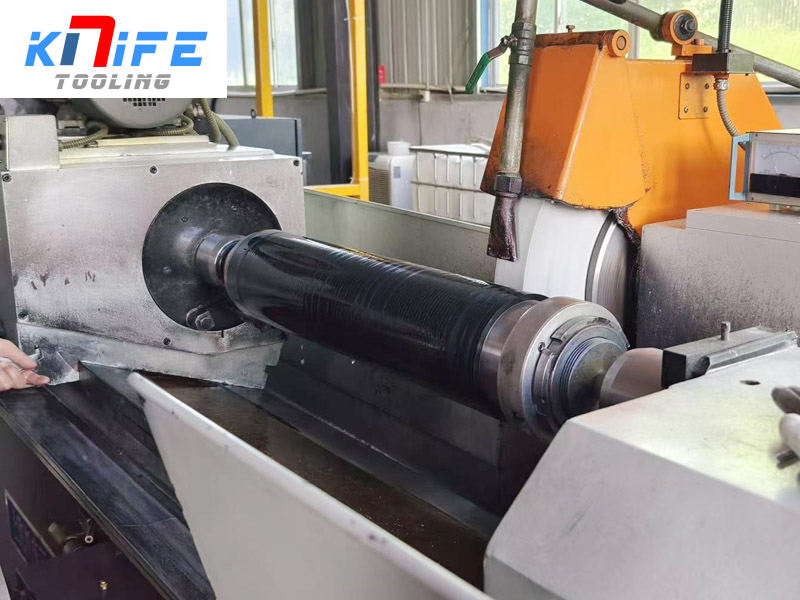

Recently, our Knifetooling technical team went to a customer's enterprise for on-site visits and technical support. During the communication, they learned that aluminum powder had adhered to the surface of the cutting tools used by the customer, which greatly affected the slitting accuracy and caused many troubles in the production process. In response to this situation, our technical team immediately launched the tool surface resharpening coaching work, striving to help the customer restore the tool performance and improve the production quality.

In the process of resharpening coaching, our technical team carefully taught customers scientific resharpening skills based on their rich practical experience and professional knowledge. Considering the usage status of different tools and the degree of aluminum powder adhesion, the team first guided customers to select grinding stones of different roughness according to actual needs, ensuring that the grinding stones could not only effectively remove aluminum powder but also avoid excessive wear on the tool surface. At the same time, to prevent the uneven force on the tool and damage to the tool body caused by excessive resharpening at one time, the team clearly informed customers of the reasonable range of resharpening quantity and demonstrated the operation steps on site, allowing the customer's staff to directly grasp the speed and strength of resharpening. In addition, the team also emphasized the key points in the resharpening process, such as the control of resharpening angle and the inspection method after resharpening, to ensure that customers could independently and standardizedly complete the subsequent tool resharpening work.

Our technical coaching achieved remarkable results. After professional resharpening, the aluminum powder on the customer's tool surface was completely cleaned, the slitting accuracy was greatly improved, and it fully met the production needs. More importantly, during the entire resharpening process, the tool body was not damaged at all, which effectively extended the service life of the tool. This achievement not only helped the customer successfully overcome a major problem in production, reduced production stagnation caused by tool failure, but also reduced the frequency and cost of the customer's tool procurement, creating tangible profits for the customer.

In the future, Knifetooling will continue to give play to its technical advantages, constantly improve the after-sales service system, and continuously provide customers with more professional and efficient technical support and coaching, moving forward hand in hand with customers to achieve mutual profit and double win results.

Recently, our Knifetooling technical team went to a customer's enterprise for on-site visits and technical support. During the communication, they learned that aluminum powder had adhered to the surface of the cutting tools used by the customer, which greatly affected the slitting accuracy and caused many troubles in the production process. In response to this situation, our technical team immediately launched the tool surface resharpening coaching work, striving to help the customer restore the tool performance and improve the production quality.

In the process of resharpening coaching, our technical team carefully taught customers scientific resharpening skills based on their rich practical experience and professional knowledge. Considering the usage status of different tools and the degree of aluminum powder adhesion, the team first guided customers to select grinding stones of different roughness according to actual needs, ensuring that the grinding stones could not only effectively remove aluminum powder but also avoid excessive wear on the tool surface. At the same time, to prevent the uneven force on the tool and damage to the tool body caused by excessive resharpening at one time, the team clearly informed customers of the reasonable range of resharpening quantity and demonstrated the operation steps on site, allowing the customer's staff to directly grasp the speed and strength of resharpening. In addition, the team also emphasized the key points in the resharpening process, such as the control of resharpening angle and the inspection method after resharpening, to ensure that customers could independently and standardizedly complete the subsequent tool resharpening work.

Our technical coaching achieved remarkable results. After professional resharpening, the aluminum powder on the customer's tool surface was completely cleaned, the slitting accuracy was greatly improved, and it fully met the production needs. More importantly, during the entire resharpening process, the tool body was not damaged at all, which effectively extended the service life of the tool. This achievement not only helped the customer successfully overcome a major problem in production, reduced production stagnation caused by tool failure, but also reduced the frequency and cost of the customer's tool procurement, creating tangible profits for the customer.

In the future, Knifetooling will continue to give play to its technical advantages, constantly improve the after-sales service system, and continuously provide customers with more professional and efficient technical support and coaching, moving forward hand in hand with customers to achieve mutual profit and double win results.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- Steel Coil Slitting Tool Selection: Knifetooling Eases Your Headache

- Why SGS Matters for Your Slitting Blades: Precision Backed by Global Certification

- Knifetooling: Professional After-Sales Technical Coaching Helps Customers Overcome Tool Resharpening

- Highlights of Knifetooling’s Ultra-Precision Slitting Knives

- How to pick the best slitting knives for best productivity